Software, Product flyer, brochures and data sheets

Search for

Press ENTER to search or ESC to closeWhy does Wingfan have so many different blade profiles and hub sizes available?

The main components of our assembled fans are 30+ different hubs and 25+ different blade-profiles. In most cases a centre boss or bushing is added to mount the fan. The configuration possibilities of the extensive modular component system can be readily manufactured to any size and operating point required with an extensive range of mounting options to suit all engines and motors, may it be electric, hydraulic or engine driven.

Why did Wingfan add PAGAFR to their existing blade materials?

Materials being used for rail applications have to meet stringent international safety standards. Wingfan has developed a special fan blade material PAGAFR (PAG Advanced Flame Retardant) that meets all fire standards worldwide regarding flammability, toxicity and smoke generation for rail applications. Our Smart Configuration System SELECT allows to choose from small and compact fans for the cooling of compressors for brake systems to large diameter fans for locomotive cooling systems.

What is the purpose of the flexible blade extensions BLEX®?

Close the gap between the blades tip and your shroud down to ZeroTip® clearance with our flexible but high-tensile BLade EXtension. BLEX® reduces turbulences and eliminates slippage leading to considerable noise reduction and maximized efficiency. Common tip clearances can be as high as 1.5% of the fan diameter. State-of-the-art BLEX® technology is available with all thermo-plastic blade profiles in the Wingfan product range.

Does Wingfan also offer fan drives (clutches)?

Do you have any assembled fans in stock?

How can the fan be assembled on my motor/drive?

Wingfan can offer an appropriate mounting solution no matter what drive type you have available in your machine or application. Exemplary installation types are: cylindrical bore, conical bore for tapered shaft and flange mounting on a pulley or a fan drive. The assembly side is distinguished between A (pusher) or B (puller).

Can I operate the fan in reverse direction to clean out the cooler?

How do I position the fan within my cowl/nozzle?

How does the shroud-type influence the performance?

Where can I get drawings and CAD (3D) models?

Can anybody interested download the Wingfan SELECT program?

Yes, please check our download area to register for our exceptionally user-friendly fan selection software to quickly find the optimal fan solution for the application at hand.

Does Wingfan also supply fans for HVAC units?

Yes, our large diameter fans are cost effective, for any HVAC application and we understand and can provide for low power consumption and noise characteristics which are important selection criteria. Wingfan’s robust yet lightweight fans can be fitted with a wide variety of centre bosses to fit any electric motor. Our weight optimized thermoplastic blade material not only increases the bearing life of the motors but are also a cost-effective cooling solution for standardized HVAC units.

How does Wingfan measure their profiles?

The measurements are carried out on our inlet side chamber test rig in accordance with the AMCA-Standard (Air Movement and Control Association). To give the best correlation to the customer’s application, Wingfan has measured its profiles in different configurations, such as nozzle/orifice plate and with an engine downstream to analyse the influence of an obstacle.

Can Wingfan also carry out a measurement including my cooling system to identify the restriction curve?

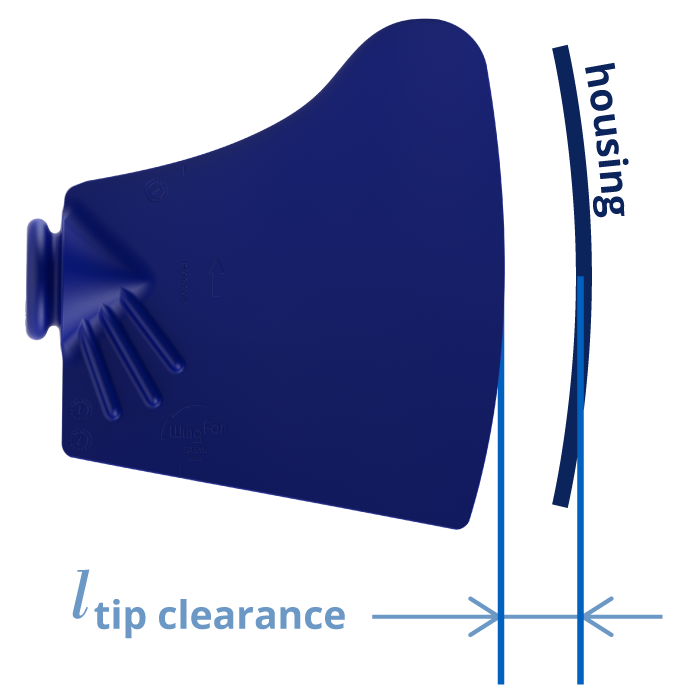

How is the tip clearance being measured, e.g. 1%?

The outer diameter of a fan is determined by the housing-diameter and the tip clearance required. This allows for interference free operation between the components. The tip clearance can be specified as an absolute measure, or as a percentage of the fans diameter. The tip clearance necessary to prevent interference of the fan with the housing varies depending on the application and type of drive. The tip clearance has an immense influence on the performance data. To achieve ZeroTip® clearance, our BLEX® blade extensions are an appropriate measure for most applications.

Example: A fan with an outer diameter of 600 mm operated in a housing with Ø612 mm equals in a tip clearance “l” with 1% (= 6 mm absolute).

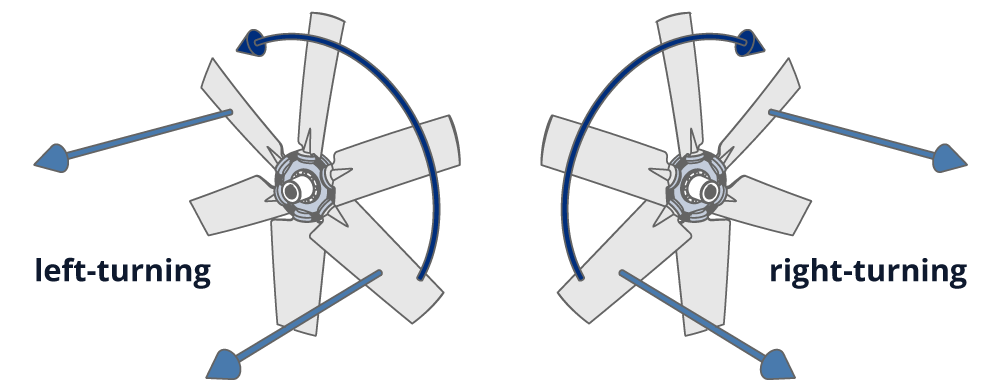

How is the fan rotation direction defined?

The direction of rotation is defined as right “R” or left “L” while facing the airflow (upstream/pressure side). Right-turning is specified as clockwise rotation, whereas left-turning is counter-clockwise rotation.

Additionally, the direction of rotation is noted on the blades. An arrow on the upstream/pressure-side also indicates the direction the fan rotates.